15

DESIGN ENGINEERS

Within engineering services SM Contact evaluates Customer’s components, customizes equipment and provides after-sales maintenance.

SM Contact engineers determine precise connection parameters and its improvement options depending on the type of application, connector or component materials, and working environment.

What materials combinations cause bimetallic galvanic corrosion? How components positioning affects electrical resistance? What is the cross-dependence of temperature resistance and components material?

Profound study and 30 year experience allows SM Contact specialists to adapt equipment and tooling to Customer’s application. The following parameters are specified: tooling dimensions and shape, splice band features if applicable, equipment type, its automation level, speed, special options and quality control devices.

Our ace of trumps – more than 1000 tooling sets database. We look for similar cases, involve engineering thought, common sense and that’s it.

SM Contact maintenance offer implies remote tracking of the machine status and connection quality. When the time for planned maintenance comes or in case of negative performance report, the alarm notification is sent to SM Contact engineers and timely service is provided.

E.g.: The punch of SM Crimp was changed after 300 000 crimps. CPk deviation is out of tolerances. SM Contact gets an alarm signal, analyses tolerance dynamics and sends recommendations to the customer: “Recommended punch change frequency: each 250 000 crimps”.

SM Contact offers not only the equipment itself, but also seminars on current quality standards, connections testing algorithms and the principles of quality control devices operation.

In 2016 we held the first Splice Crimping Seminar for around 100 customers and partners, presenting splicing tips, connection qualification principles, and pitfalls of equipment and tooling adjustment.

Preparing for the second round of interviewing colleagues, I minimized my expectations. How could it be possible to get enough stunning information week by week? I wasn’t right! Guilty as charged.

Read More

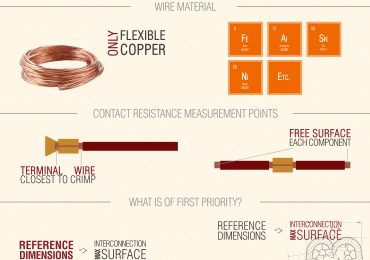

In the previous “Useful tips” we investigated widely applied industrial crimp norms and arrived at the conclusion that they do not concern exotic materials (aluminum, steel, fiber, etc.) and components (e.g. battery tab, PCB, sensor). So, how to evaluate your such-like connection? For these cases there is a help of IEC 60352-2 norms giving test schedules and techniques for crimp connections.

Read More

SM Contact Engineering has done significant work to investigate the most common industrial crimp standards in terms of components requirements, dimensions, compression rate and contact resistance. Standards in question are PSA 9634115099, VW 60330, USCAR-21, TDK-EPCOS F61207-R3308 and Bosch N42AP 730 (2014).

Read More