STANDARD FEATURES

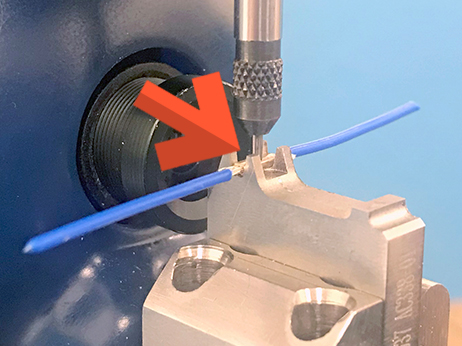

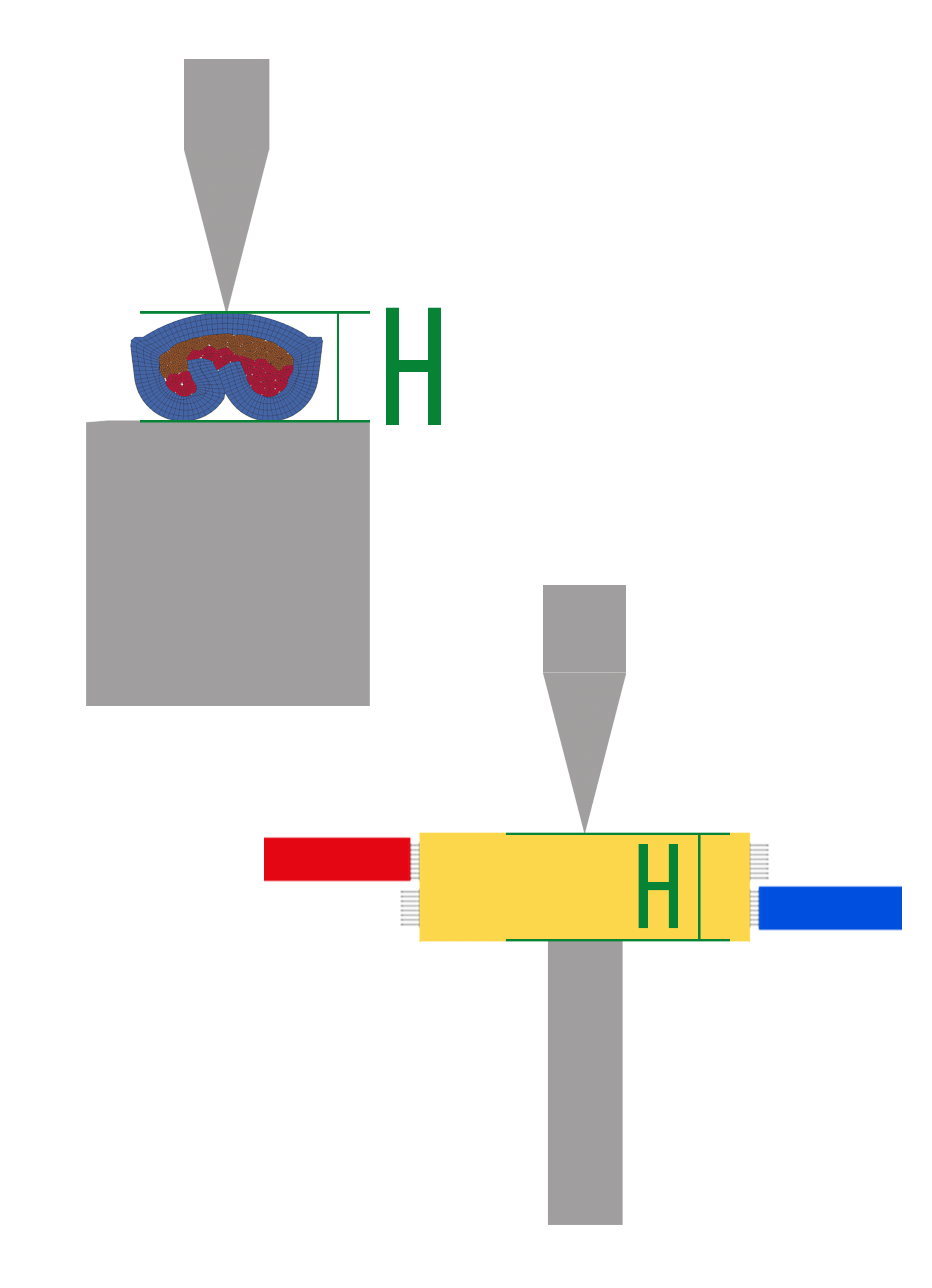

Clincher

Clincher follows the shape of a sample, which excludes the risk of improper positioning of a sample and false results. Сlincher is quick-changeable and it allows to measure different connections with one device.

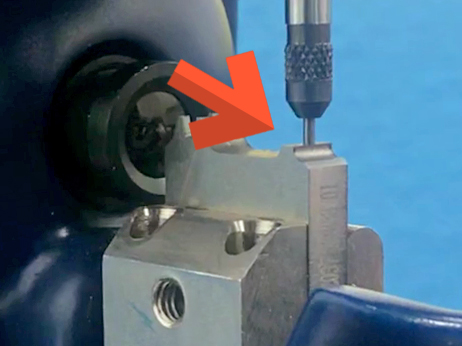

Calibration

Flat surface of the clincher is used to set zero position for measurement.

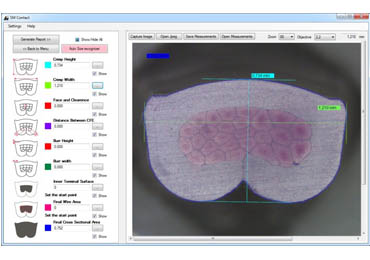

Camera

Built-in camera displays enlarged view of the work area facilitating the operator‘s work. Captured images and measurements are saved on SD card or can be transferred to PC by Bluetooth.

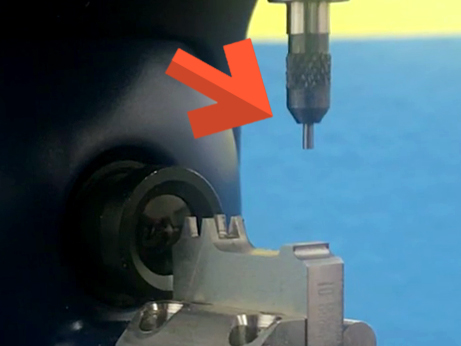

Spring-loaded measuring pin

Spring-loaded measuring pin provides sufficient pressure to measure the sample, but doesn‘t deform it.

Extensive assessment of the quality

CrimpiX can be synchronized with Viso software: measurement results will be automatically added to Viso report on connection comprehensive quality check.

ADVANTAGES

CrimpiX vs caliper

The jaws of a caliper doesn‘t fit the shape of a crimp. As a result it cannot always get to the bottom of a crimp or the sample can turn. In both cases obtained height values will be wrong. Another reason of improper measurement results is overcompression of the sample.

CrimpiX for splice connection

CrimpiX guarantees proper positioning and correct measurement values thanks to a customized design of a clincher – it follows the shape of a crimp. Overcompression is impossible due to spring-loaded pin – it brings pressure sufficient for measurement, but without a risk of sample deformation.

CrimpiX vs micrometer

Due to the shapes mismatch within micrometer measurement crimp may be positioned between the anvil and the pin randomly, both in the longitudinal and in transverse planes. Thus, the accuracy of measurement depends on the skills of operator.

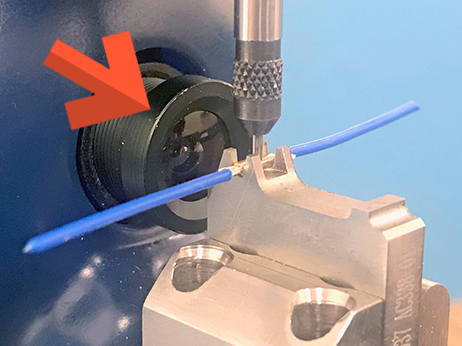

CrimpiX for standard crimp

For standard crimp height measurement CrimpiX is used with flat plateau clincher. Accuracy is provided by built-in camera: it fixes sample positioning, simplifying detection of the operator’s error.