2022

AUTO PIERCING technology for magnet wire: SM Contact starts production of P-type splice band

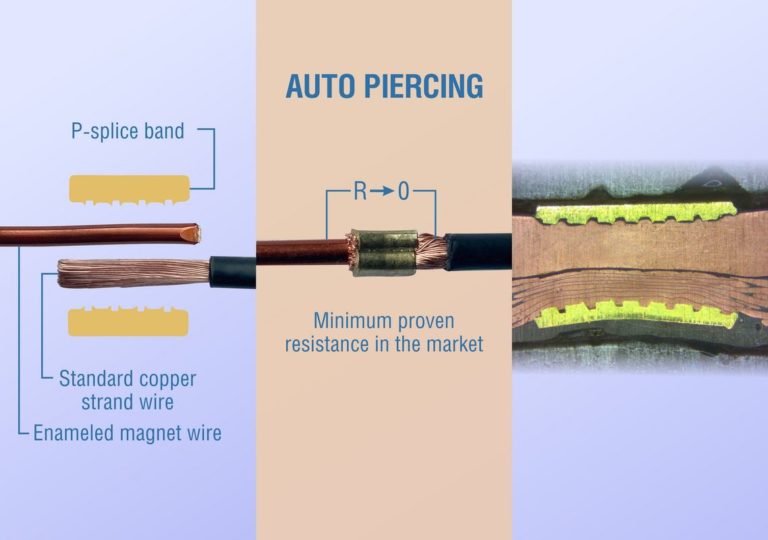

Auto piercing by splice crimping is a cost-effective alternative to IDC terminals, soldering and spot welding in magnet wire applications. SM Contact launches production of splice band for piercing of enameled wires – P-type splice band, in addition to the standard one.

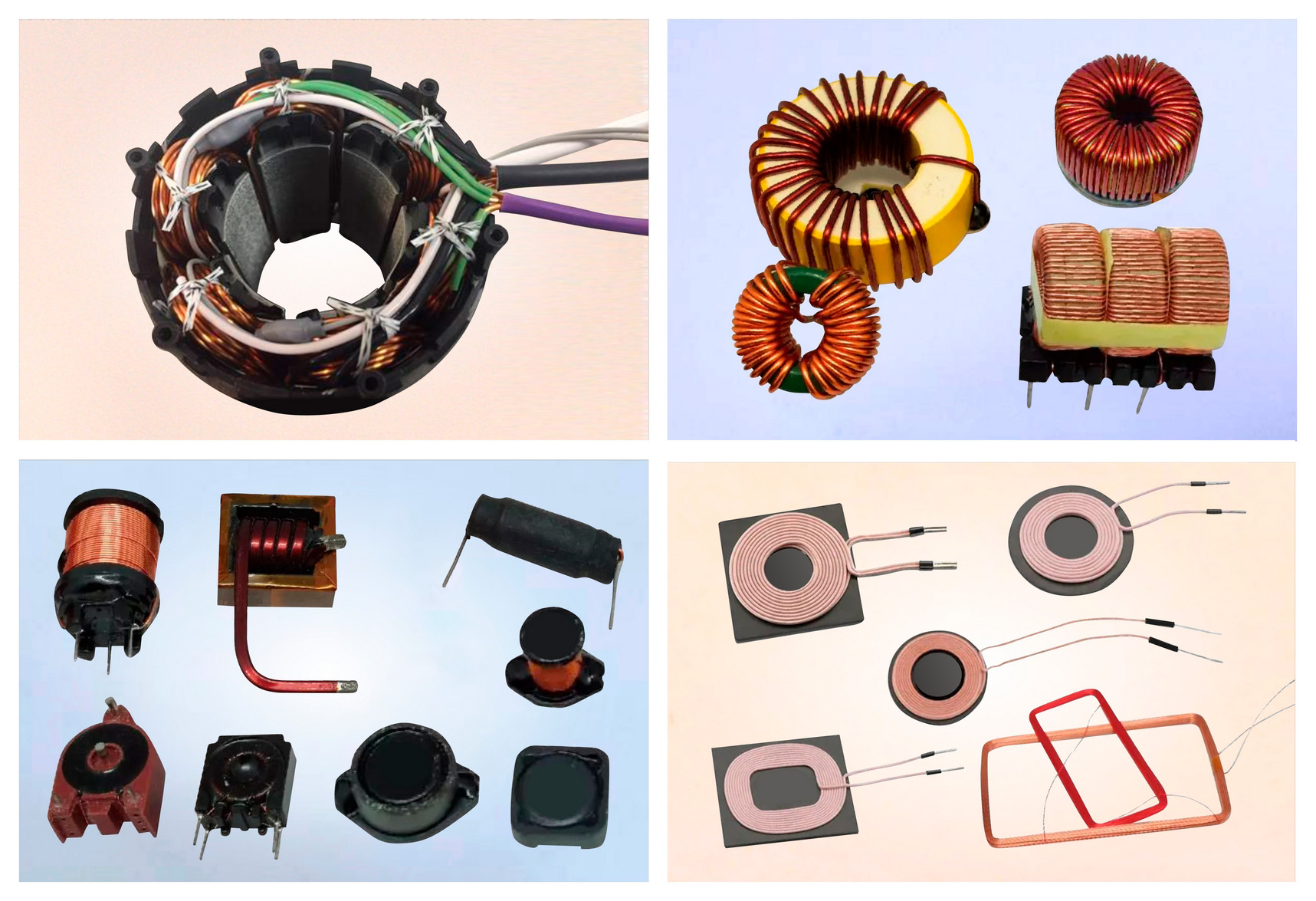

Magnet-piercing splice band is leveraged in connecting power/signal and magnet wires (coils) in electric motors, e-mobility (EV charging stations) and household appliances. It enables one-step reliable gas-tight connectivity between standard power wire and insulated magnet wire. Auto piercing technology offers advantages of a low cost and fast cycle time.

Advantages of auto piercing technology:

1 – Repeatability:

stable quality with the mechanical process and control of the splice band shape => stable electrical connection without component damage risk.

2 – Reduced cycle time:

by eliminating soldering and stripping operations (0.3 sec).

3 – Qualified and validated connection supported with data sheet:

all required parameters, such as pull force, compression rate, contact resistance, are reached by computer simulation and laboratory studies using a certain splice band.

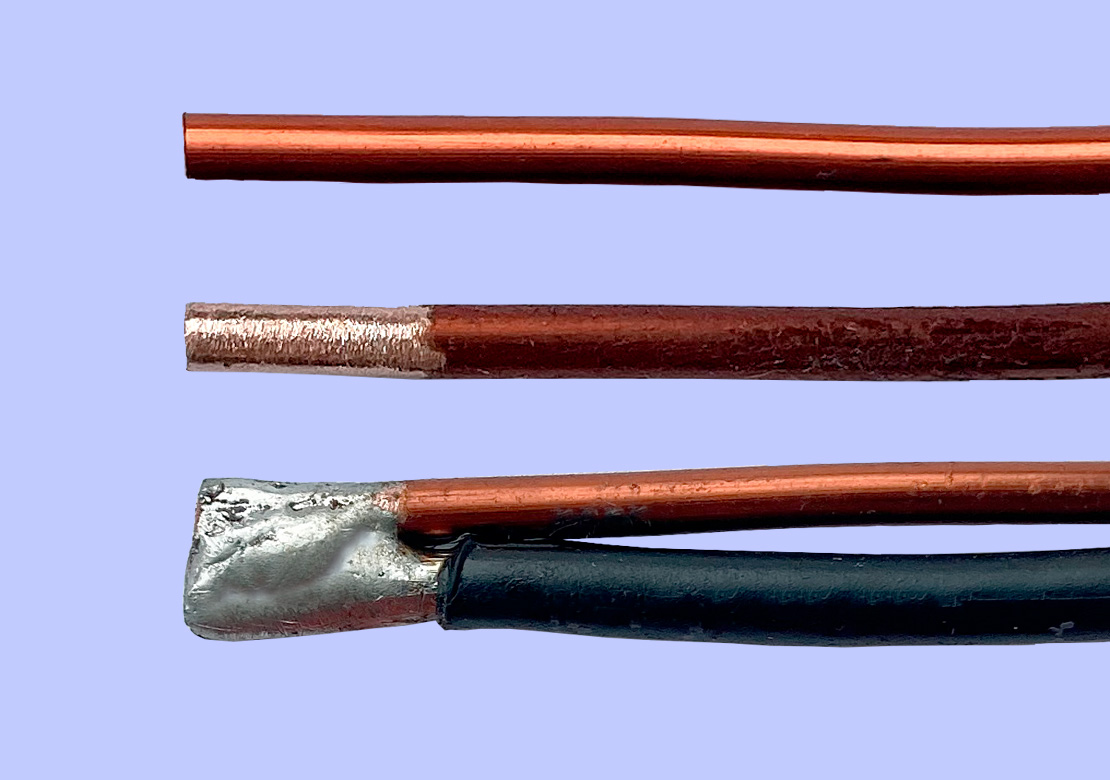

Standard process vs. Technology of splice crimping with P-splice band

P-type splice band provides a method of connection of an enameled magnet wire directly to wire or component.

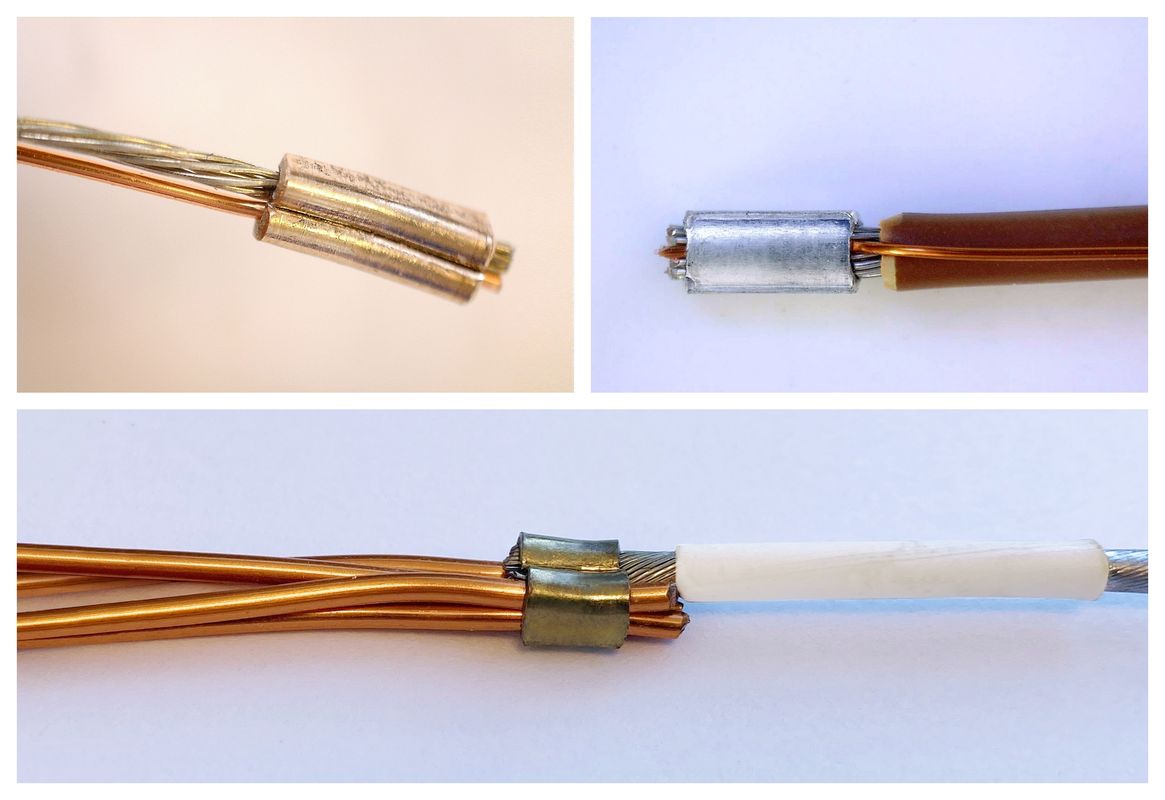

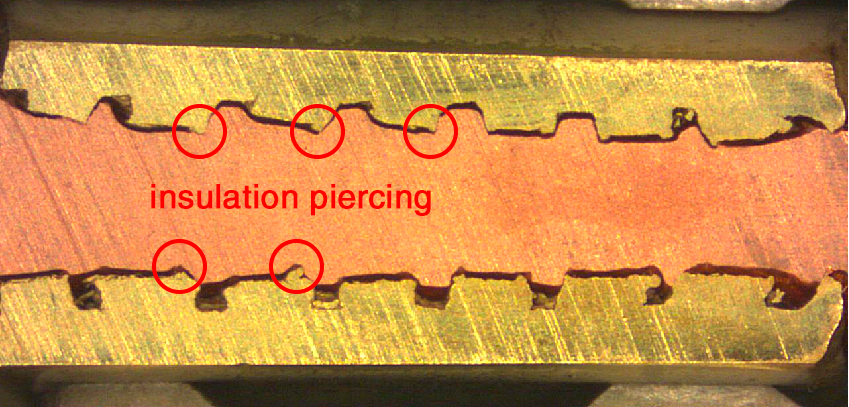

P-splice band profile

|

| Piercing serrations, penetrating varnish insulation used on copper and aluminium magnet wires: |

|

P-splice band materials

SM Contact offers P-type splice band mostly in LA, also in CN.

| LA (Brass) |

CN (Copper Nickel) |

|

| Typical applications | Standard applications | Perfect corrosion resistance. Weldable. |

| Composition | Brass CuZn30 | CuNi9Sn2 |

| Resistance (K coeff.) | 3.55 | 8.5 |

| Temperature range | -80..+120°C | -80..+400°C |

|

|

Advantages of using P-type splice band by SM Contact with SM Crimp equipment:

1 – Zero tooling damage risk:

splice band characteristics are considered for connection qualification and machine settings.

2 – Optimal connection properties:

required parameters specified in the data sheet are reached by using a certain splice band – produced by SM Contact. Third-party splice band may not allow achieving these characteristics.

Please contact our Project Team for details: smcontact@smcontact.eu, +34 919490803