2022

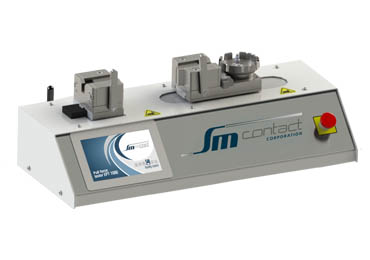

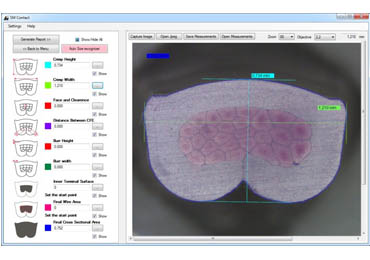

Automatic crimp height adjustment function is implemented in the new generation of SM Contact splice crimping machines – SM Crimp V8. Up to 16 connections with different crimp heights can be stored in the tooling cassette´s memory slot.

Read More