STANDARD FEATURES

Splice band

Splice band is defined according to the type of application and environment temperature range: splice band type and material (brass, brass with tin coating, chrome-nickel, chrome-nickel with tin coating, stainless steel), thickness (0.2 – 0.53 mm), length (1.5, 2, 3, 4, 6, 7 mm), and height.

Crimping tooling set

Tooling set includes clincher, anvil, punch, punch guide, and cutting block.

Such parameters as clincher type, clincher size, and punch tip shape are customized for the application.

Inclined clincher surface and smooth cutting surface guarantees efficient operation.

Integrated memory keeps application parameters, recommended settings and spare parts list.

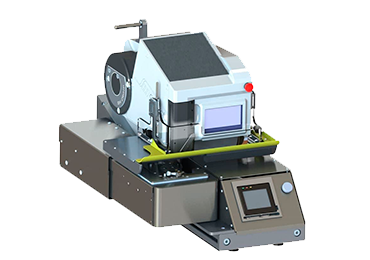

Automatic fixture

Allows accurate positioning of the components being adapted to its quantity, shape and size. Fine adjustment of the height position of components. Fixture moves between loading and work area automatically with servomotor.

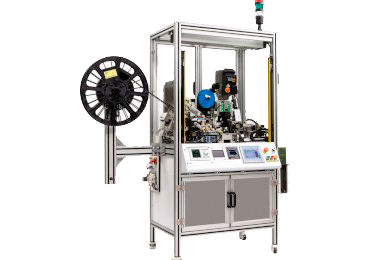

Automatic manipulators

Automatic manipulators transfer components in three axes from one unit to another to provide straitening, cutting, stripping, twisting, splice crimping and unloading.

Each manipulator is customized to fit application. It prevents damage and guarantees precise and safe operation.

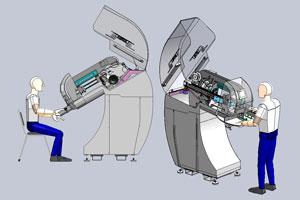

Sitting and standing position of operator

Electrical setting of machine height allows sitting and standing position of operator. Ensures a comfortable way of working for the operator (from 850 to 1050 mm).

Safety cover

Polycarbonate cap covers work zone of SCS, dividing it from the loading area. It provides operator`s safety and allows loading of components while the previous connection is being processed.

Final products container

Container for operator to collect proper parts fast.

OPTIONS

Crimp Force Monitor (CFM)

CFM captures force-time curve and detects any deviation from the quality tolerances. System works with many types of splicing and crimping machines and suites well to any application requiring inline monitoring of forces.

The reference curve of CFM corresponds to crimping force, but in fact it can reflect such quality deviations as: missing wire strands, inaccurate components positioning or crimp height, insufficient insulation strip length, insulation in the splice area, etc.

CFM also allows to adjust automatic cutting and/or rejection of defective items.

Straightening, cutting, twisted and stripping station

Wires straightening is proceed by combing.

Cutting unit cuts the wires after splice crimping in order to get wires of a same length. It suits wires of up to 1,5 mm2 diameter.

Stripping length (until 7 mm) and knives penetration into insulation is set by micrometer. Waste removal in cutting and stripping area is performed by a vacuum cleaner.

Movements of all the stations are driven by a step motor.

POKA YOKE

Allows controlling utilization of NG/NOK components. If CFM detects quality deviation and estimates connection as NG/NOK, then machine stops operation and waits until NG/NOK component is placed to POKA YOKE bin.

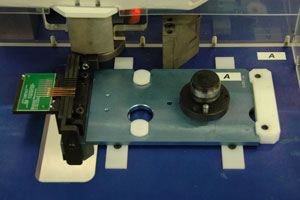

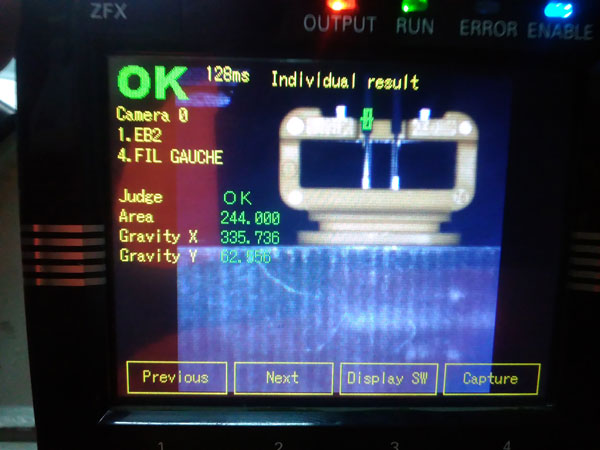

Camera quality control

According to the selected program, high/low definition camera takes picture and controls components` position, color and stripping length. High or low definition is selected depending on size of components.

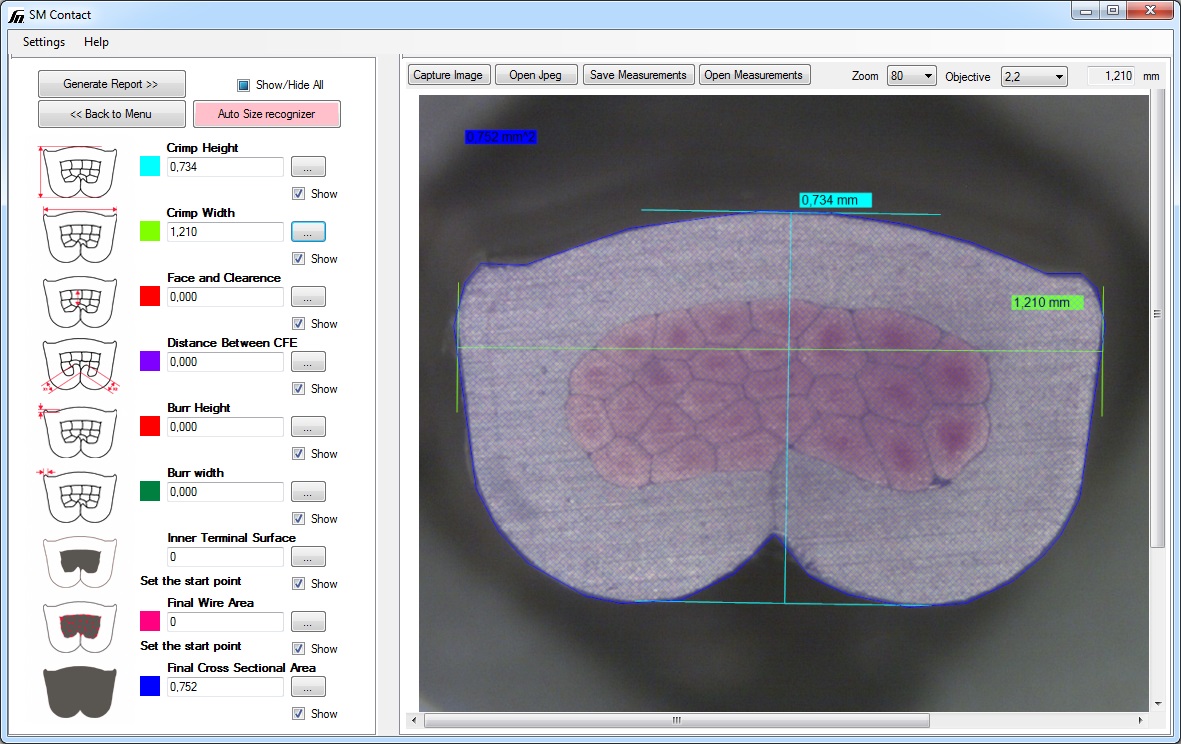

Quality control equipment

Laboratory equipment allows to control whether the splice quality matches industry norms or any other special requirements. Check our micrograph laboratories, pull force and crimp height control tools, as well as specialized measurement software.

ALTERNATIVE ENERGY

AUTOMOTIVE

CIVIL ENGINEERING

ELECTRONICS

LIGHT INDUSTRY

MASS MARKET

MEDICAL

RAILWAY

CORDS

DIODE & RESISTOR

FILAMENT

WIRE & CAPACITOR

WIRE & COIL

WIRE & DIODE

WIRE & LEADFRAME

WIRE & PCB

WIRE & METAL TAB

WIRE & SENSOR

WIRE & METAL TAB

WIRE & RESISTOR

WIRE & METAL TAB

WIRE & WIRE

WIRE & METAL TAB

PCB & COAXIAL CONNECTOR

WIRE & METAL TAB

WIRE & PIN

WIRE & METAL TAB

WIRE & PLASTIC CONNECTOR

WIRE & METAL TAB

WIRE & PLUG ADAPTER

WIRE & METAL TAB

WIRE & THERMAL FUSE

WIRE & METAL TAB

ссылки на доп. картинки

0-1

0-2

0-3

0-4

0-5

0-6

1-1

1-2

2-1

3-1

3-2

4-1

4-2

4-3

4-4

4-5

5-1

6-1

7-1

7-2

7-3

7-4

7-5

8-1

8-2

9-1

9-2

9-3

9-4

9-5

9-6

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

11-1

11-2

11-3

11-4

11-5

11-6

11-7

11-8

11-9

11-10

11-11

11-12

12-1

12-2

12-3

13-1

13-2

13-3

13-4

13-5

13-6

13-7

13-8

13-9

14-1

14-2

14-3

14-4

14-5

14-6

15-1

16-1

16-2

16-3

16-4

16-5