2023

Enameled wire connection in one go

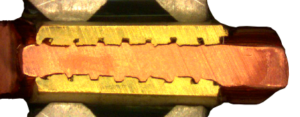

SM Contact offers auto piercing technology by splice crimping for processing enameled wire. It is a cheaper but reliable alternative to IDC terminals, soldering and spot welding in magnet wire applications.

P-splice band of own production has a proprietary serrated profile penetrating various varnishes and coatings used on copper and aluminum magnet wire.

Duration: 0:39

Enamel-piercing P-type splice band can be leveraged in:

– Following products: electric motors, e-mobility (EV charging stations), household appliances, in computer, audio and video devices, in industrial electronics, watches and even mars rovers.

– Following applications, for connecting wires to: coils, electric motors, transformers, speakers, alternators, solenoids, inductors and small appliances.

One-step process

Connection is produced of an unstripped magnet wire directly to wire or component. Auto piercing technology:

- Saves cycle time by excluding stripping and soldering -> reduces costs.

- Well-controlled process.

- With no heating.

- With RoHS and REACH compliance for P-splice band materials.

- Easily scaled for different production volumes.

- Ensures repeatable high quality of the product.

Resulting interconnection:

– highly reliable,

– robust,

– gas-tight,

– vibration resistant.

Please contact our Project Team for details: smcontact@smcontact.eu, +34 919490803