2025

SM Contact developed the state-of-the-art solution for coil manufacturers. Just replace your IDC for magnet wire.

Read MoreWIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

WIRE & METAL TAB

ссылки на доп. картинки

0-1

0-2

0-3

0-4

0-5

0-6

1-1

1-2

2-1

3-1

3-2

4-1

4-2

4-3

4-4

4-5

5-1

6-1

7-1

7-2

7-3

7-4

7-5

8-1

8-2

9-1

9-2

9-3

9-4

9-5

9-6

10-1

10-2

10-3

10-4

10-5

10-6

10-7

10-8

10-9

10-10

10-11

10-12

11-1

11-2

11-3

11-4

11-5

11-6

11-7

11-8

11-9

11-10

11-11

11-12

12-1

12-2

12-3

13-1

13-2

13-3

13-4

13-5

13-6

13-7

13-8

13-9

14-1

14-2

14-3

14-4

14-5

14-6

15-1

16-1

16-2

16-3

16-4

16-5

Reproducible quality

Splicing as a mechanical process allows getting reproducible high quality. With the same tooling and splice band the quality of a product stays the same from cycle to cycle.

Adaptable to product

Tooling is designed individually for each product so that the splice fits perfectly the components and form reliable connection.

Gastight

The deformation of the components and the splice during the splicing process guarantees gastight connection.

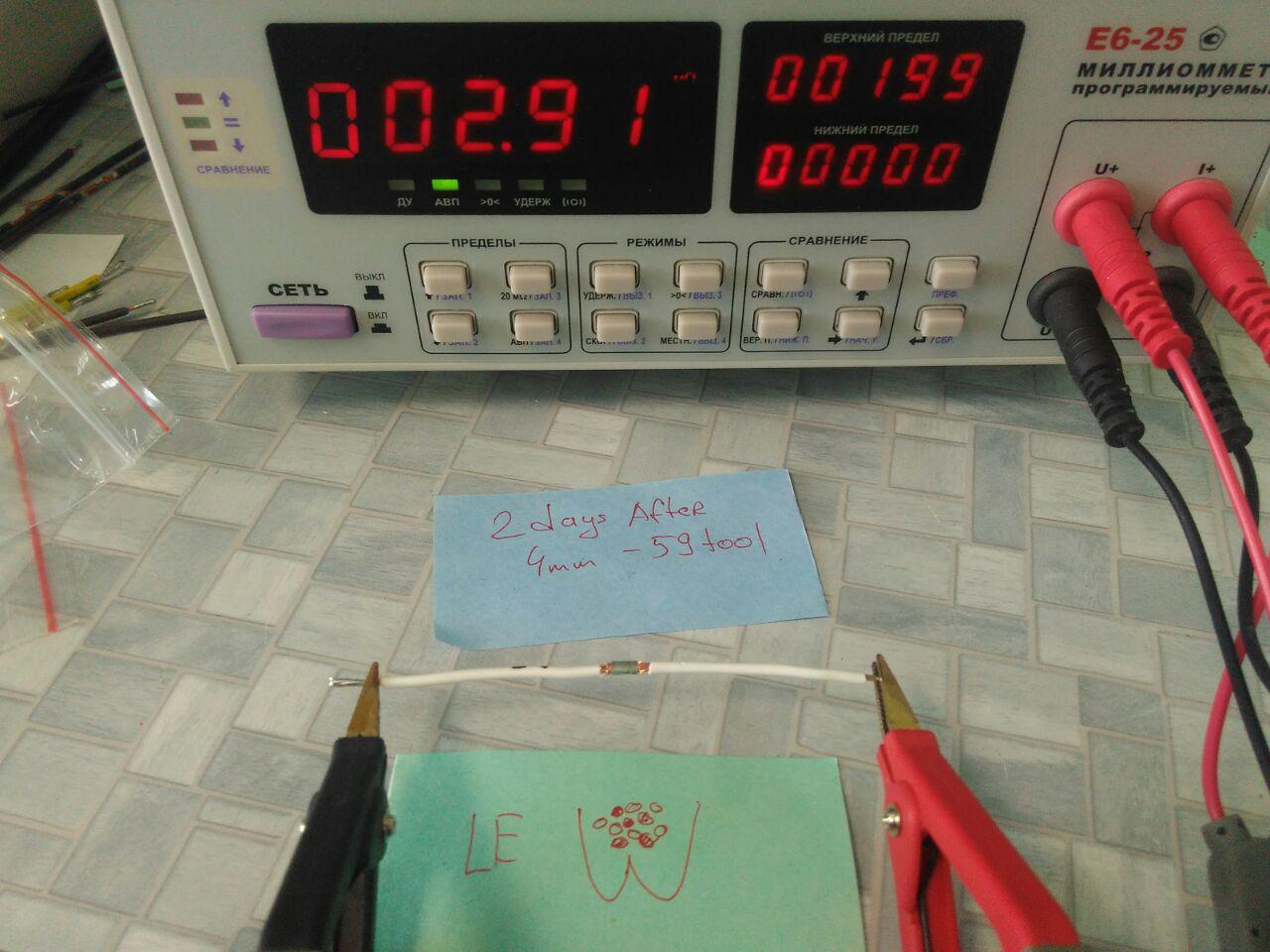

Low electrical resistance

Connection and tooling engineering guarantee stable low electrical resistance preventing loose strands, misaligned connection and other defects.

Deformation and vibrations resistance

Splice crimping doesn’t involve heating unlike soldering, thus it keeps components out of burning or melting risks and guarantees good behavior under deformation and vibrations.

Compact

Splice allows to make compact and constant size connection with minimum dimensions such as 0.46*0.24 mm cross-section connection for an artificial cardiac pacemaker. Space saving feature is ideal for sensors, bulbs, heating elements, etc.

Universal

Splice connection can be performed with various types of components (PCBs, wires, coils, sensors, plastic connectors, filament, etc.), materials (fiber, Teflon, chrome, steel, etc.) and size.

Quality control

Splice quality is easy to be controlled unlike soldering with a help of inline systems (Crimp Force Monitor, camera position and color control, Poka Yoke, etc.) or standalone laboratory equipment (cross section, pull force, crimp height measurement, etc.).

Easy to go

Thanks to automation it’s possible to make up to 2000 splices per hour without any experience in splicing.

Cost-efficient

Splice spare parts are cheaper than ones for welding and soldering and it need to be changed rarely: each 300 000 – 3 000 000 assemblies depending on spares and components type.

1. SPLICE BAND DEFINITION

We define splice band features depending on type of application, component materials, working environment and temperature range.

What you get?

Splice band material (LA, LE, CN, CE, IN), type (standard serrated, M-type), thickness (0.2 – 0.53 mm), length (1.5, 2, 3, 4, 6, 7 mm), and height.

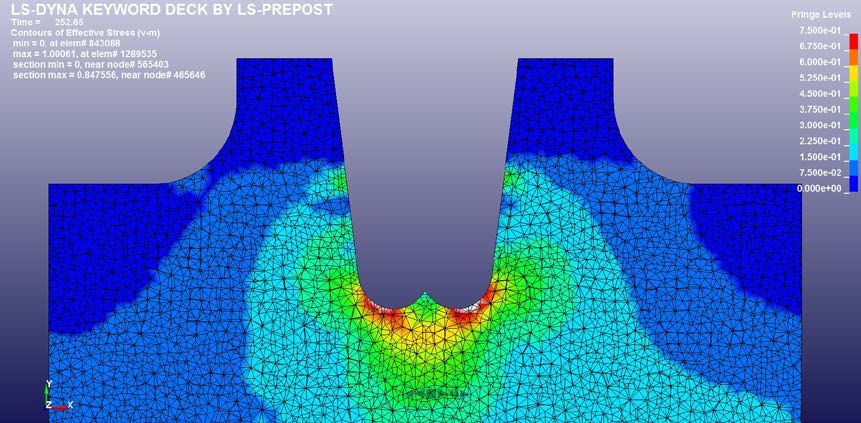

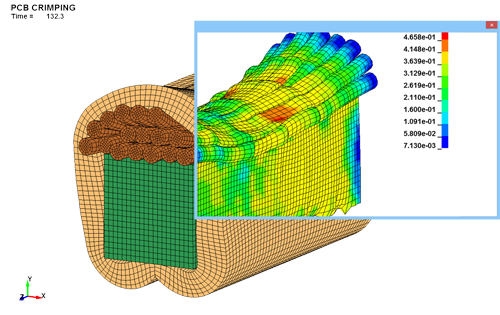

2. TOOLING DEFINITION

With a help of FEA software and database of former realized connections, we build computer model of tooling and simulate strains and stresses during splice crimping.

What you get?

Equipment type, clincher type (standard, CI-type or special) and size, punch tip shape (standard or double trumpet), special tool necessity definition.

3. SPLICE CONNECTION SIMULATION

With a help of FEA software we build components computer model of defined type and materials and simulate strains and stresses during splice crimping.

What you get?

Optimal connection parameters and its improvement options are specified to match industry norms and Customer’s demand (connection dimensions and optimal components positioning, compression rate, internal stress levels, contact resistance, and interconnection surface).

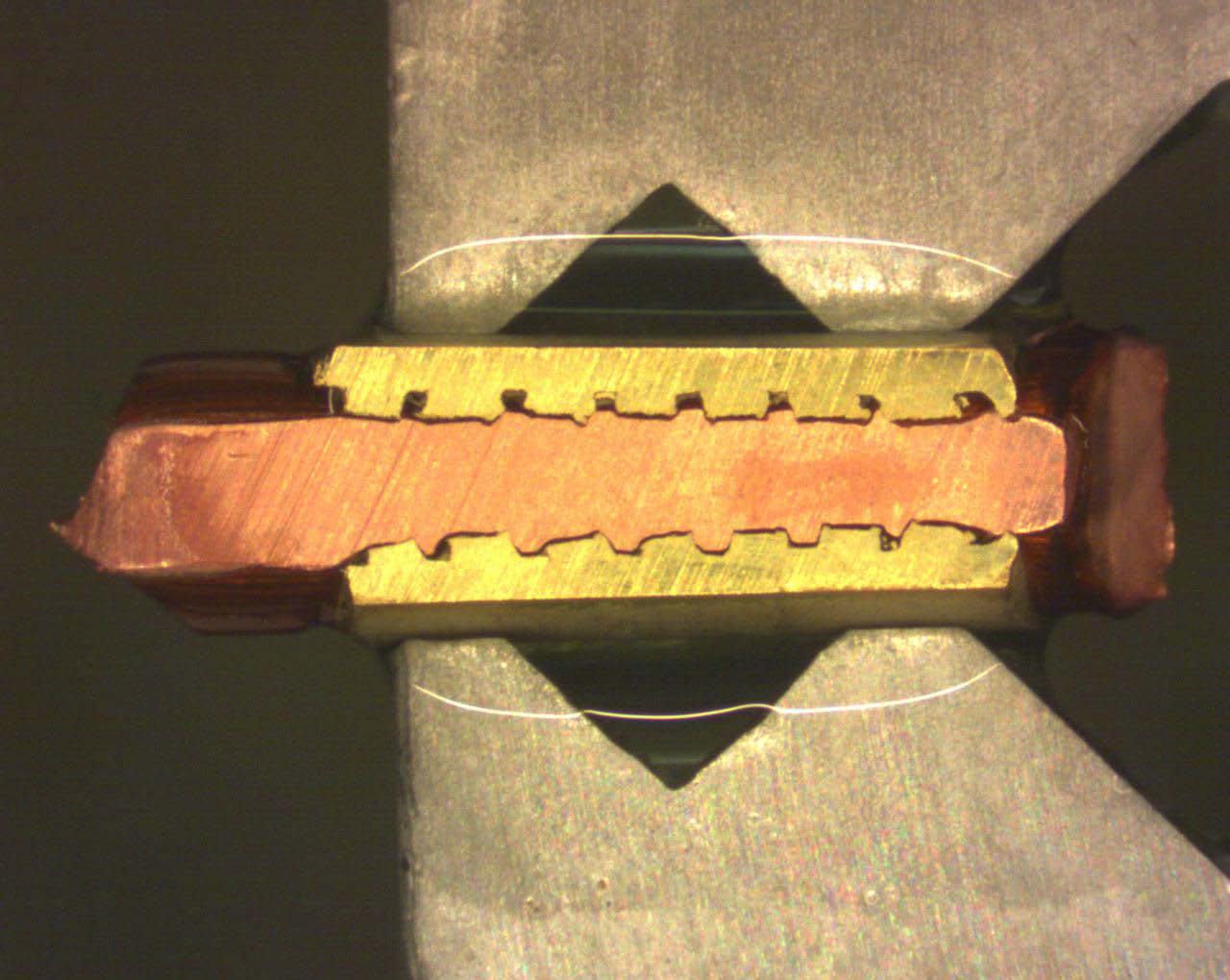

4. LABORATORY TESTS

We make samples and perform laboratory study: pull-force, electrical resistance, and galvanic corrosion measurements, as well as thermal stress test and cross-view research.

What you get?

Report and datasheet with precise connection parameters matching splice/crimp norms and validated for different splice heights and compression levels according components tolerance (optimal connection cross-view shape, tooling requirements, target connection dimensions for machine adjustment, etc.).

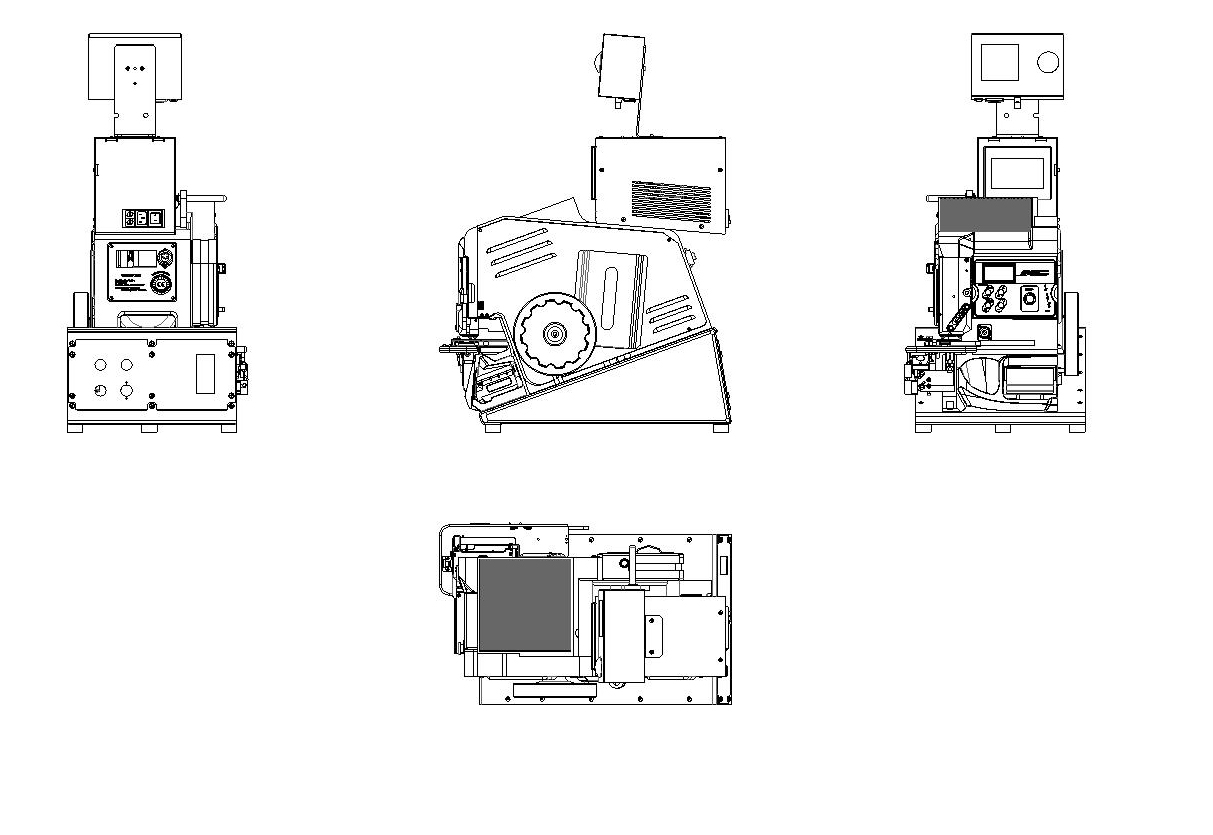

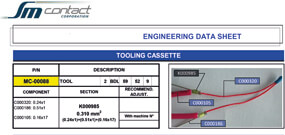

5. EQUIPMENT MANUFACTURING

Engineering department adapts automation level, speed, special options and quality control devices.

What you get?

Splice crimping equipment customized for Customer’s application, as well as for quality, automation, cost and production volume requirements.

6. FPC SOLUTION

– Control List with all optimal connection dimensions and tolerances.

– Viso 6microsection measurement software.

– Annual re-validation of a connection.

What you get?

Automated splice quality control and timely support from SM Contact engineering staff.

Check out splice equipment options! Each machine can be customized to particular components, environment, automation level, and production volumes.