2025

New patented IDC pin for magnet wire allows up to 80% cost savings

p-in connectors

SM Contact offers the state-of-the-art solution for electromagnetic coil manufacturers.

Patented solution with P-in p-in connector to reduce the cost of magnet wire connections through increased throughput

P-type pin for magnet wire brochure

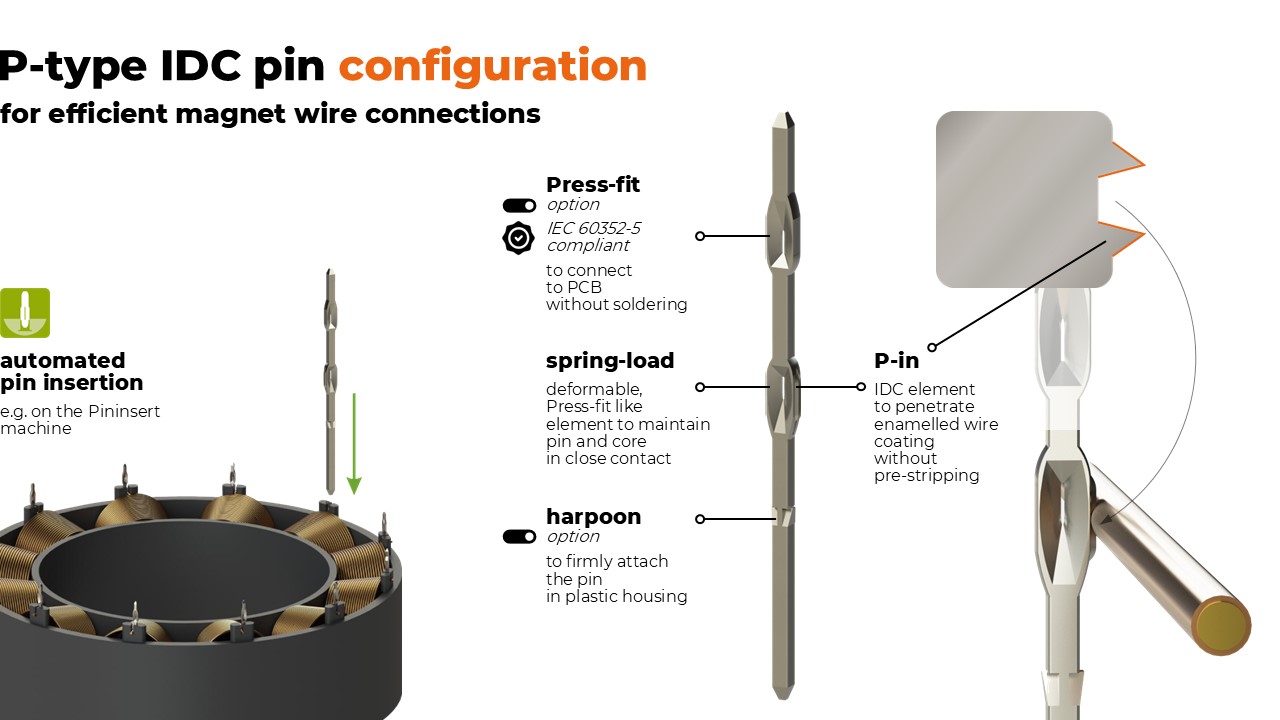

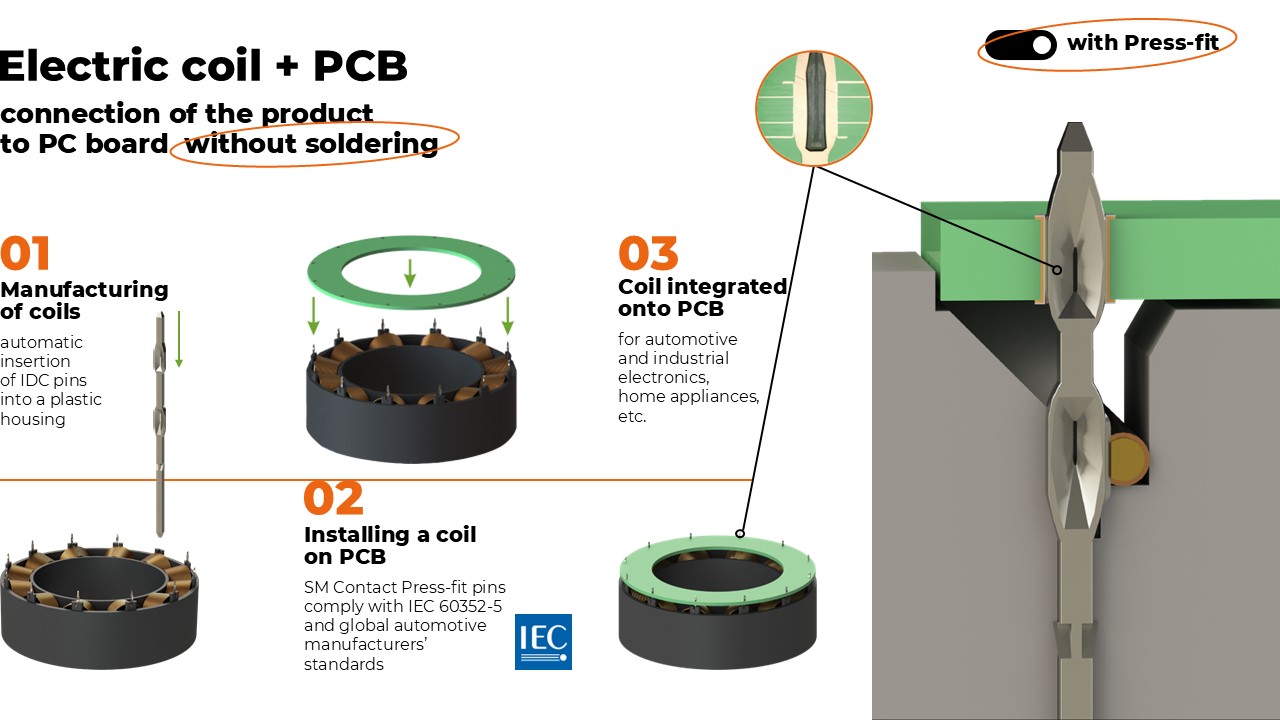

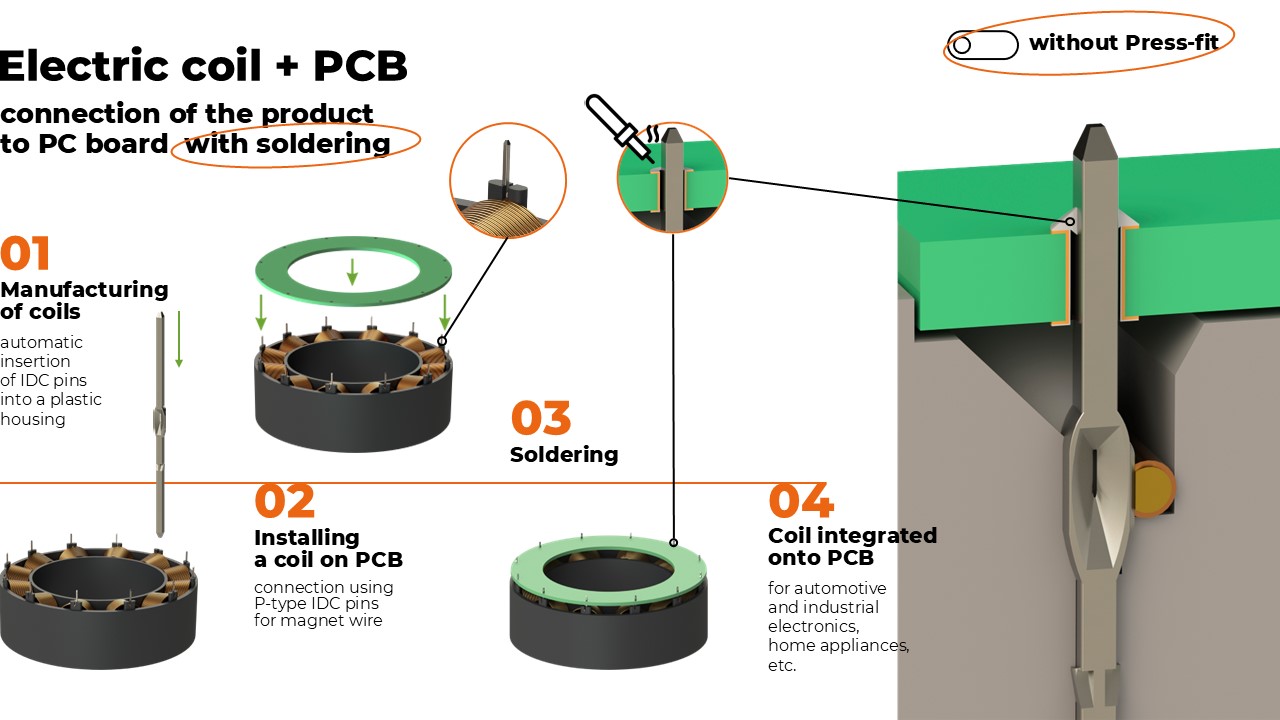

IEC 60352-5 certified SM Contact Press-fit technology for plated PCB holes offers the possibility to connect our terminals with PCBs as well.

Various Press-fit sizes are available.

Press-fit stamping on the P-type IDC pin is an option. A similar connection to the printed circuit board can be made with soldering.

270 million pins supplied in 2024 by SM Contact

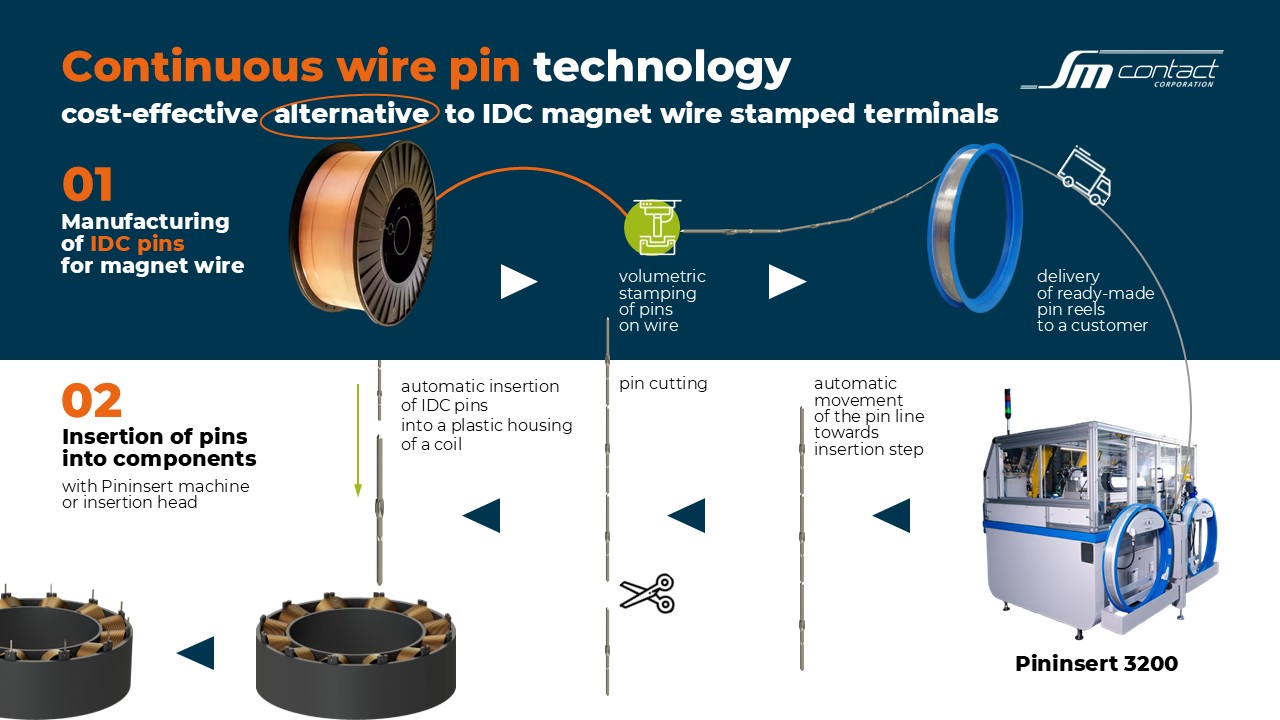

Continuous wire technology – alternative to stamped terminals

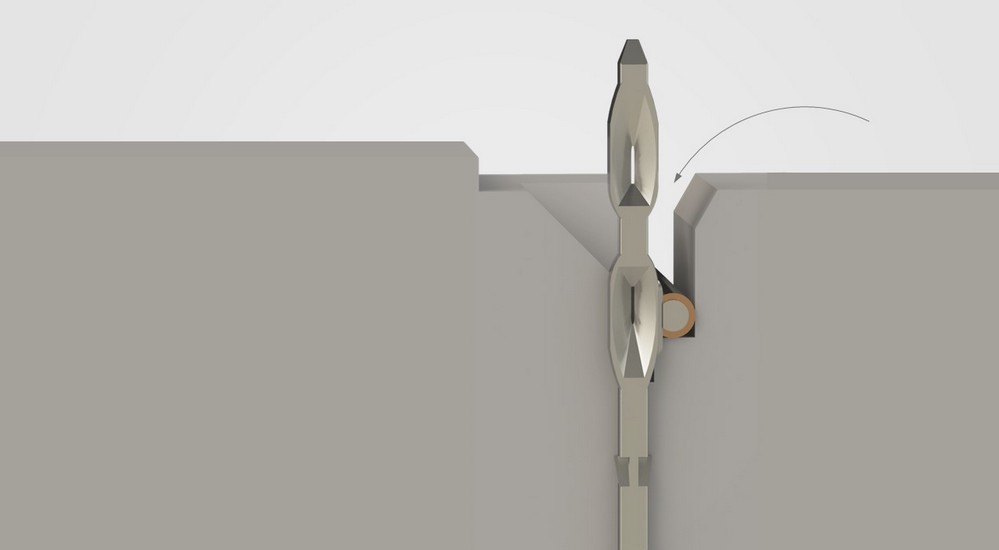

Pins are fed into the Pininsert machine from plastic reels mounted on unreelers. Each reel contains between 30 000 and 200 000 pins of the specified configuration, lined up end-to-end. They are winded onto the reel as a continuous wire. This format is optimal for SM Contact technology with automatic pin insertion.

During the pin manufacturing, notches are made on the wire corresponding to the required pin length. These are the points where they are cut during insertion in the components. Chamfers on both ends of the pin also ensure accuracy and speed of installation.

Available shapes for IDC pins

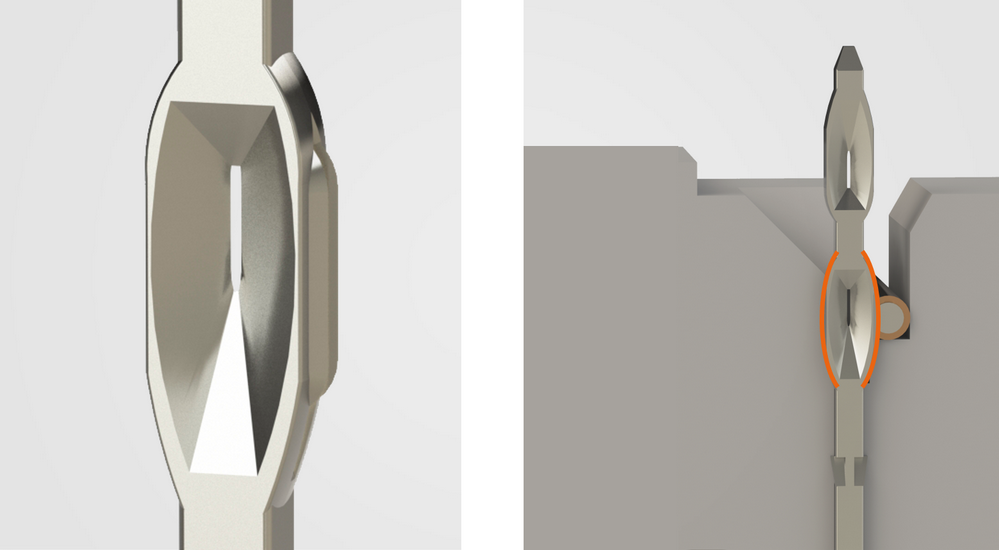

Each IDC P-type pin can be stamped to ensure better retention in the component:

– Press-fit,

– harpoon

– and their combinations on a single pin

The type of stamping is determined by the need for soldering and installing the coil on the PCB.

Advantages of continuous wire pin technology:

– flexibility: variability of pin length, position and number of stampings

– cost-effectiveness: unlike strip stamping (stamped terminals), this method of manufacturing does not involve material loss and expensive molding tools

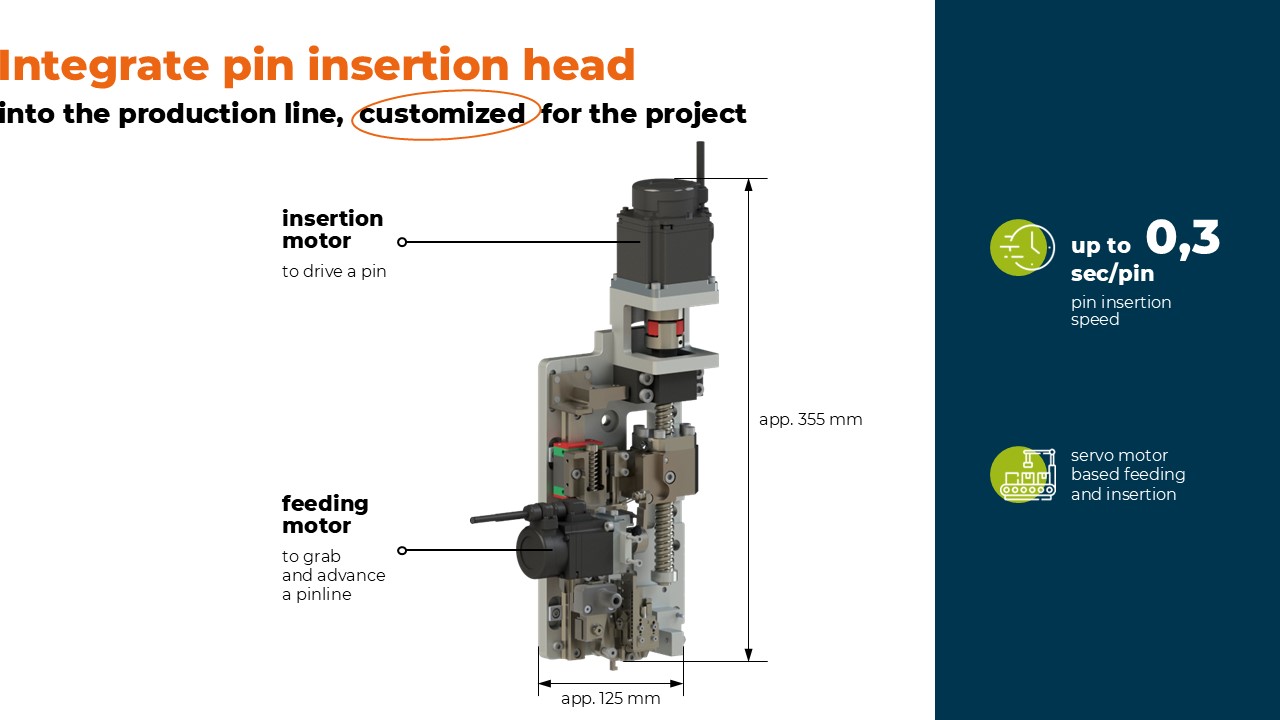

Integrate pin insertion head in your production line

When it is required to integrate pin insertion operation in the production line, we provide insertion head alone. It can be built into a coil winding line or a component assembly line.

SM Contact Pininsert equipment involved in the integration: i.e. signal exchange, conveying system. In this case we offer different options depending on the customer’s machine configuration.