O-PIN Connectors

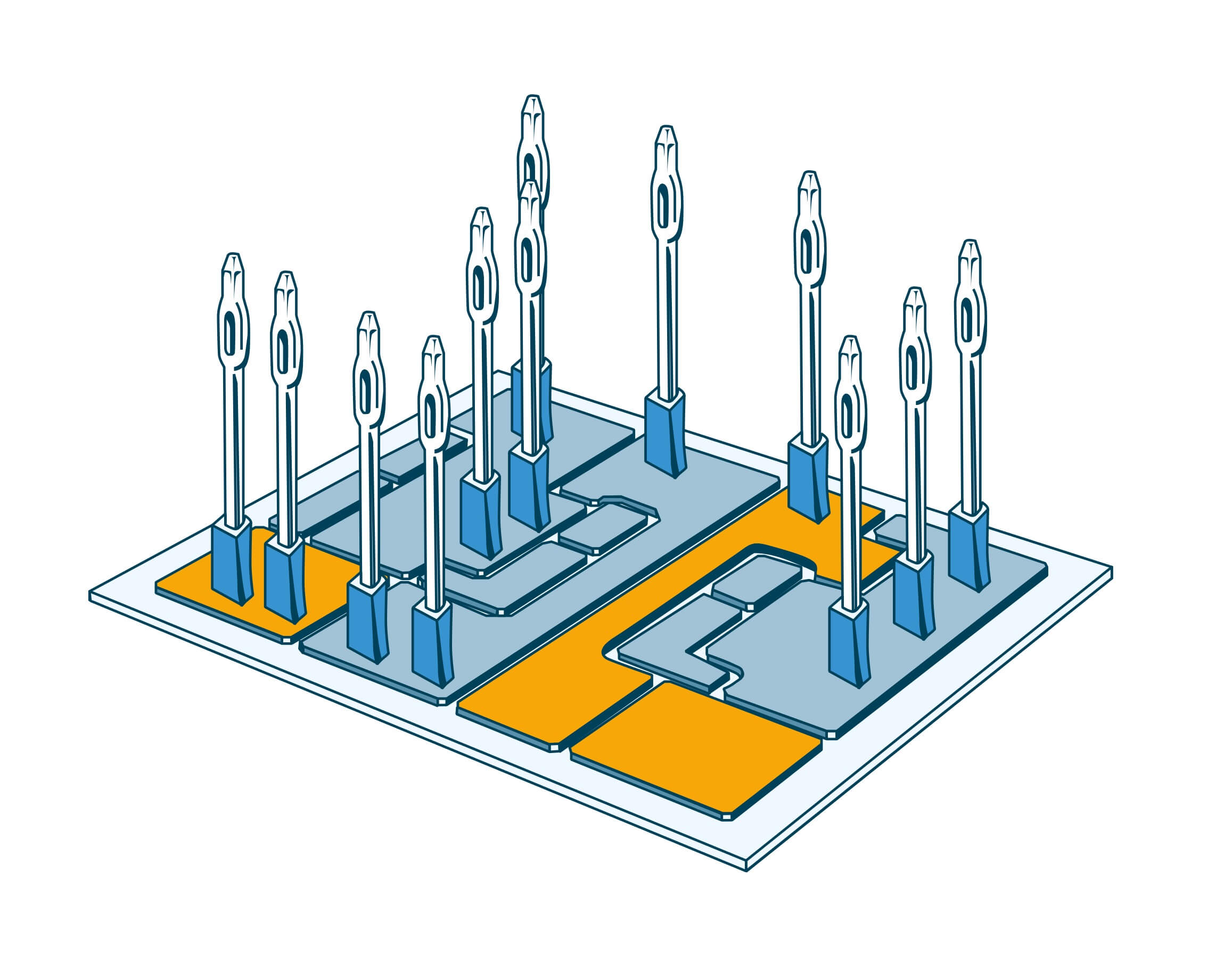

Next-Generation O-PIN Connector Terminals for Superior IGBT module

Introducing O-PIN connector terminals—the advanced solution designed to replace outdated insertion-based connections in IGBT module. Engineered for effortless installation, unmatched reliability, and flawless assembly, these high-performance connector terminals eliminate the drawbacks of traditional copper sleeve designs while delivering superior durability and precision for power electronics.

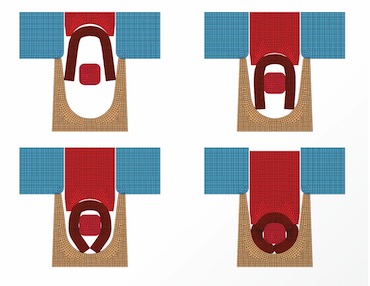

The Limitations of Traditional Connector Terminals in IGBT modules

Insertion-based connector terminals create significant challenges in high-power IGBT applications, leading to inefficiencies, defects, and costly waste. Key issues include:

- Pin damage risk during insertion, compromising long-term reliability.

- Extreme tolerance sensitivity, causing misalignment or pin slippage in high-current circuits.

- Inclination-based scrap due to imperfect connections, increasing production costs.

O-PIN Connector Terminals: Optimized for IGBT Performance

Unlike conventional connector terminals, O-PIN technology leverages high-precision splice crimping for superior electrical and mechanical performance in IGBT modules.

Key advantages:

– Zero insertion damage – Ensures consistent pin integrity and eliminates assembly risks.

– Vibration-resistant compression – Maintains secure connections in high-stress environments.

– Repeatable precision – Guarantees flawless contact surface flatness for reliable power transfer.

– Cost-efficient production – More affordable than copper sleeve alternatives without sacrificing quality.

By eliminating the need for complex multi-factor analysis (material, friction, thickness), O-PIN connector terminals streamline manufacturing while reducing defects—making them the ideal solution for high-performance IGBT modules.

Upgrade to O-PIN Connector Terminals for Superior IGBT Module Assembly

Make the switch today and revolutionize your production process with O-PIN connector terminals—delivering faster, more cost-effective, and highly efficient assembly for IGBT modules. Say goodbye to the frustrations of outdated pin-insert systems in passive element packaging and embrace a smarter solution.

Optimized Packaging for Seamless IGBT Module Production

To maximize efficiency in your IGBT module assembly line, O-PIN connector terminals are available in two convenient packaging formats:

- Bandolier Packaging (Preferred)– Ideal for automated assembly processes. The connectors are delivered in a continuous strip, enabling smooth O-Pin Jig manipulation and indexation, followed by DBC assembling, Reflow soldering, and final Module release—without manual handling.

This format minimizes downtime and ensures precise positioning every time. - Bulk Packaging– Suitable for flexible assembly needs, providing cost-effective storage and handling.

Choose Bandolier packaging for high-speed, error-free production, or Bulk packaging for smaller-scale operations.

The supply of O-pin already including interface surface connectivity for DBC assembly, permits to manage overall inclination of pin tip (max inclination+- 1º) better in unique process, rather than accumulating errors from sleeve assembly and insertion processes.

Either way, O-PIN Connectors are designed for hassle-free integration into your manufacturing workflow.