STANDARD FEATURES

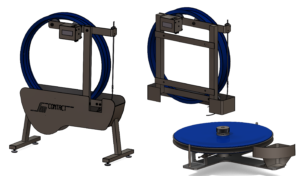

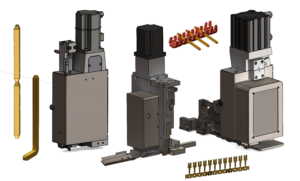

Pins unreeling systems

There are various pin feeding systems according to each pin type: end-to-end pins floor-mount unreeler, carrier pins unreeler for bandolier pins, terminal unreeler.

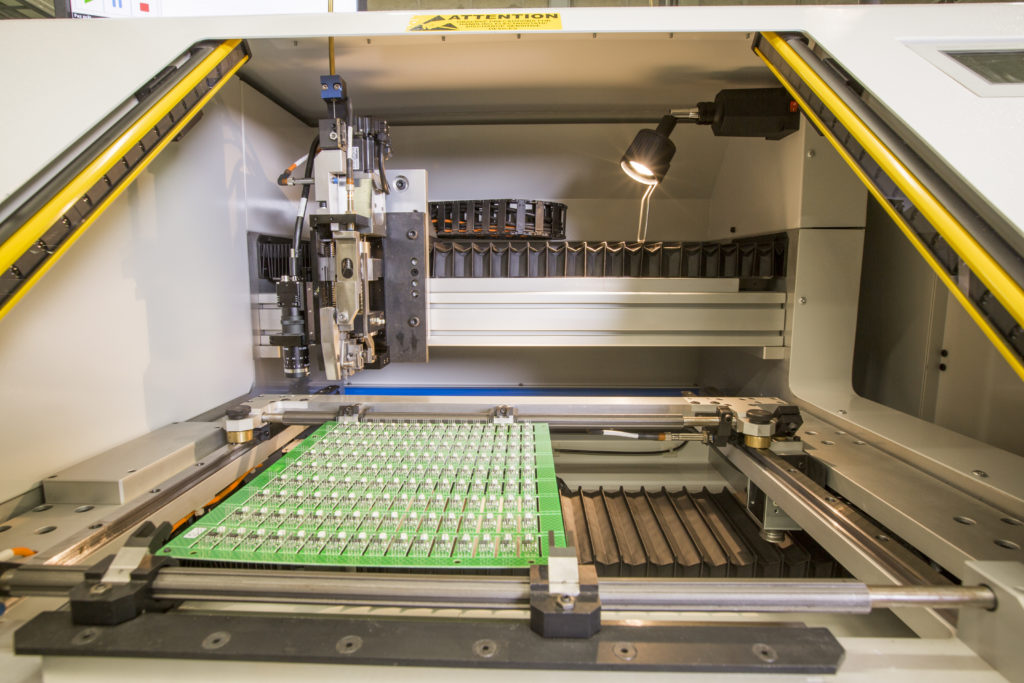

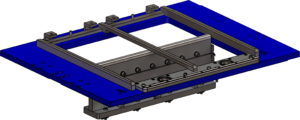

Universal table for PCB

400 x 400 mm universal table includes movable clamps to fix PCB plates of various dimensions and 10/20 mm stroke anvil to support PCB at insertion point. Thanks to it there is no need to change fixture when changing to new application.

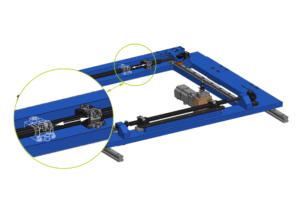

Y table for plastic connectors

Y table allows to load special removable fixture for plastic connectors. Fixtures have centering finger for correct positioning and can be equipped with alignment supports that will fix each connector.

Using two fixtures speeds up the process: while one is operated, operator loads the components to the second one.

Electrical insertion head

Electrical insertion head is fully interchangeable which simplifies change to the new application. There are several types of insertion heads according to the pin types: end-to-end, right angle, U-band (bandolier) or terminals. Insertion accuracy is highly stable and equals ±0,05 mm (CPK > 1,68).

Insertion depth is controlled by encoder and can be programmed to one-hundredth of a millimeter in the PC editor whereas equipment of other brands should be mechanically set. Thus there is no need in mechanical adjustment for each new series.

Insertion technique involves the use of precut round or square wire with acceptable section from 0,3 to 1,5 mm (with servo-drive head) or 1 mm (with pneumatic head).

Indexation system

The pin is fixed in the insertion head one step before cutting position, which decreases the tolerance of pin length and thus provides cutting and insertion precision.

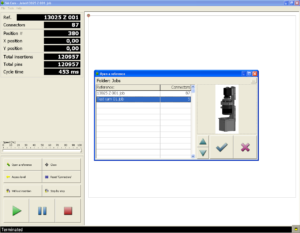

Easy-to-operate PC interface with standard PC keyboard & mouse

OPTIONS

Lighting & safety beams

Safety beams detect foreign object presence and stop the machine. This feature as well as work area lighting guarantees operator’s safety.

Automatic components loading/unloading

Electrical belt conveyor to load and unload components to/from Pininsert set in line with other equipment.

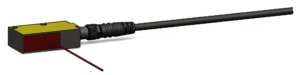

Components position laser control

Components position laser control detects wrong positioning, sends an error message on the screen and doesn’t let the machine work till the component is placed correctly.

Insertion height camera control

Low/high definition camera with integrated logics for pin height insertion control.

Insertion camera control

Special camera determines the position of 3 extreme holes in the PCB and, on this basis, calculates the position of all the holes and insertion points correspondingly.

Pin presence laser control

Pin presence laser control lets the machine differ empty slots and already inserted pins. New pins are inserted into the empty slots only and other positions are skipped.

Insertion force control

System controls each insertion and compares it to the reference values of insertion force. In case of deviation machine stops automatically or gives an alarm sound.

Force data export to Excel

System allows to download all the insertion data in Excel format.

Poka Yoke

Parts indicated by laser or insertion force sensor as defective are to be thrown into special container. Until these parts are detected inside of the container, the machine wouldn’t continue operation.

Barcode reader