9 Aug

2016

2016

Useful tips from Splice Crimping Seminar: splice crimping vs. terminals

9/08/2016

What are the main differences between splice crimping and standard terminals?

Splice crimping

- Splice is a connection between two or more components of any type: wire, tab, PCB, coil, sensor, diode, etc.

- Each splice connection is designed individually according to the shape, material, production process of a Customer, environment of final product processing, etc.

- Splice connection is up to 20% cheaper than standard terminal connection.

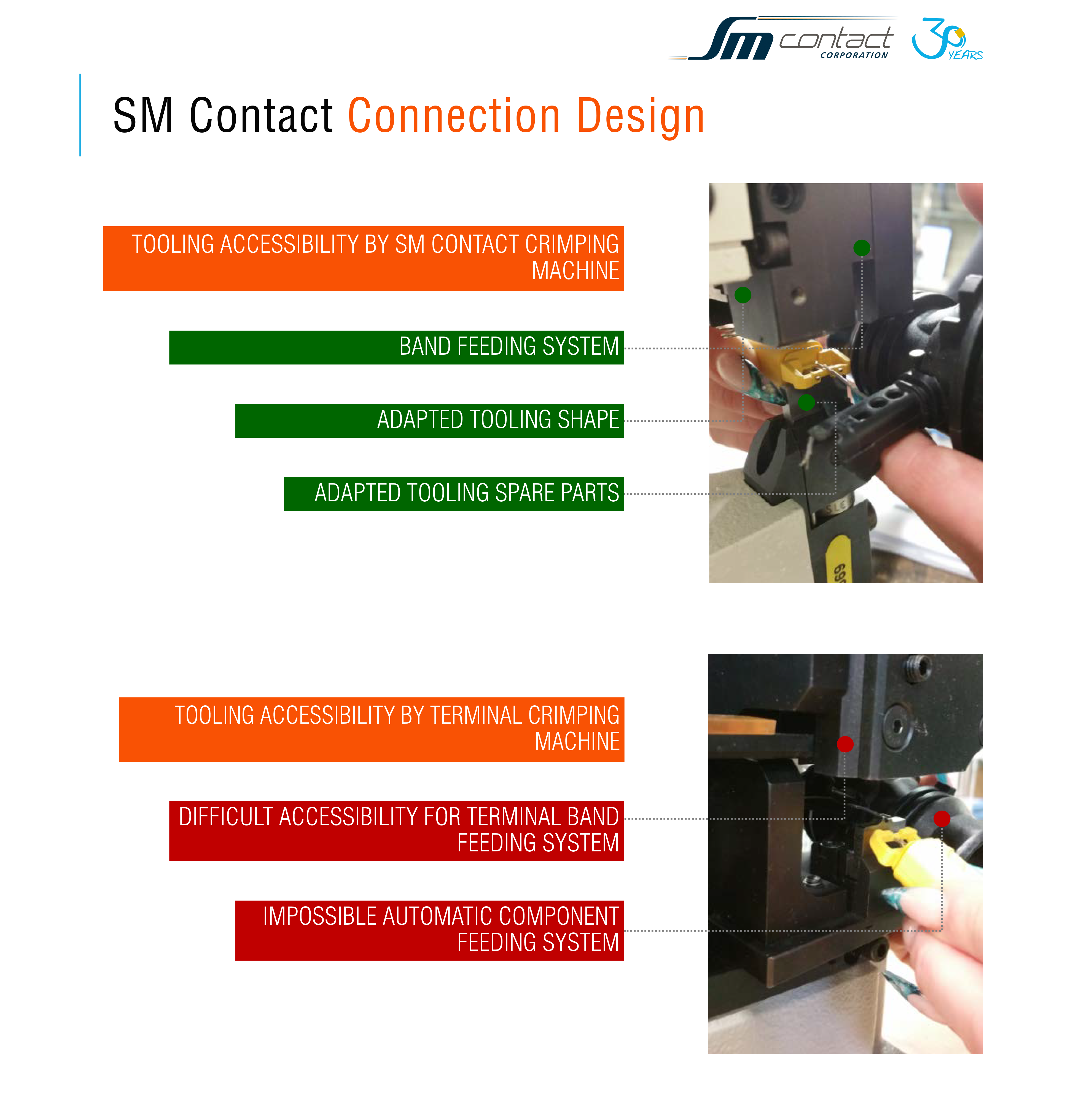

- Splice connection provides easy tooling accessibility for manual and automatic processing. There are enough place between tooling parts to place components.

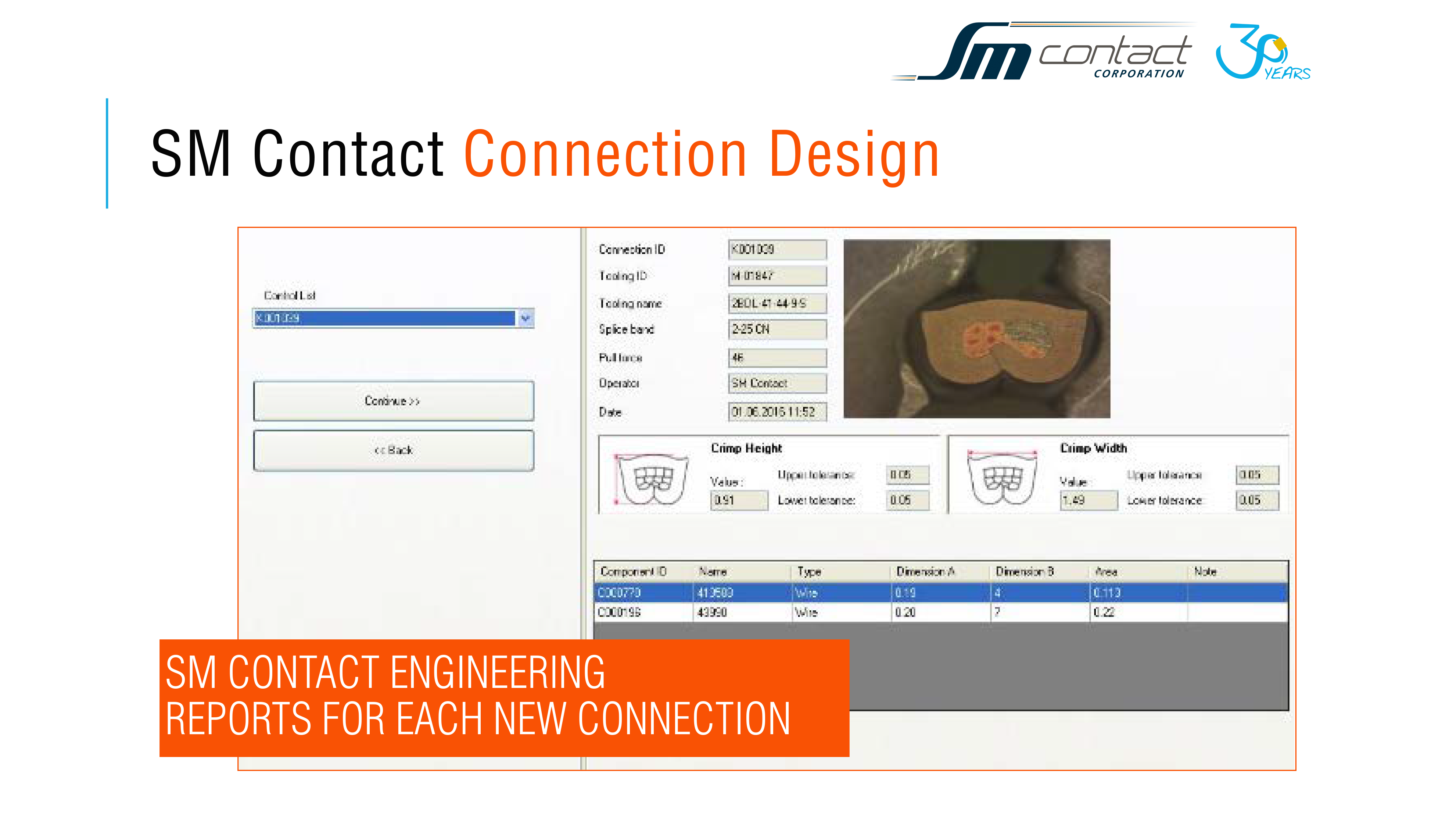

- Splice crimping with connection qualification guarantees good connection quality.

Standard Terminals

- Standard connection is a connection between wire and terminal ONLY.

- Standard terminal is to be chosen from the catalogue. In case of special Customer’s requirements, customized stamping tool must be manufactured.

- Standard terminal connection is up to 20% more expensive than splice connection.

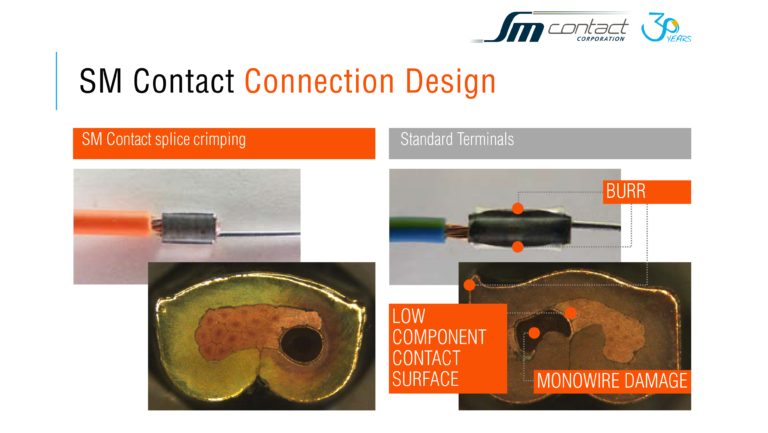

Standard terminals are characterized by difficult tooling accessibility both for manual and automatic processing. - Standard terminals can cause connection defects if they are not adapted to the component dimensions: burrs that can damage connection and lead to short circuit; wire damage and small contact surface increases resistance, makes electricity go along the crimp and results in heating.

Splice vs terminals quality

Splice vs terminals tooling accessibility

SM Contact report for each connection

Next “Useful tips”:

- Compression – resistance – pull-force. Part 1

- Compression – resistance – pull-force. Part 2

- Splice crimping vs. welding

- What do industrial crimp norms say about splice connection?

- IEC 60352-2 international standard as a gate for exotic splices