2023

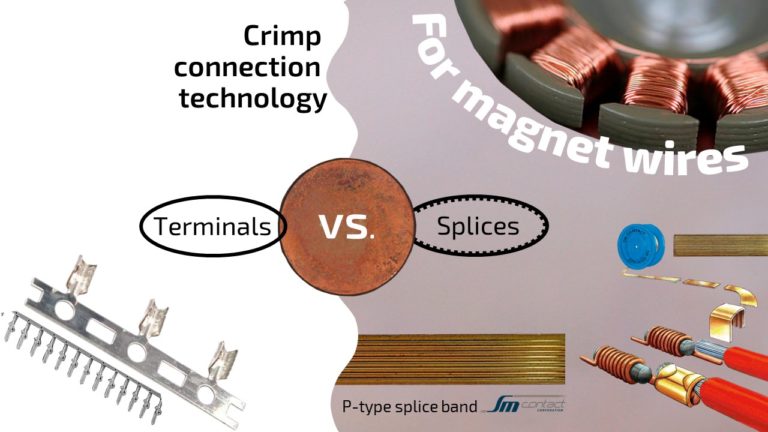

Magnet wire solutions: terminals vs. splices

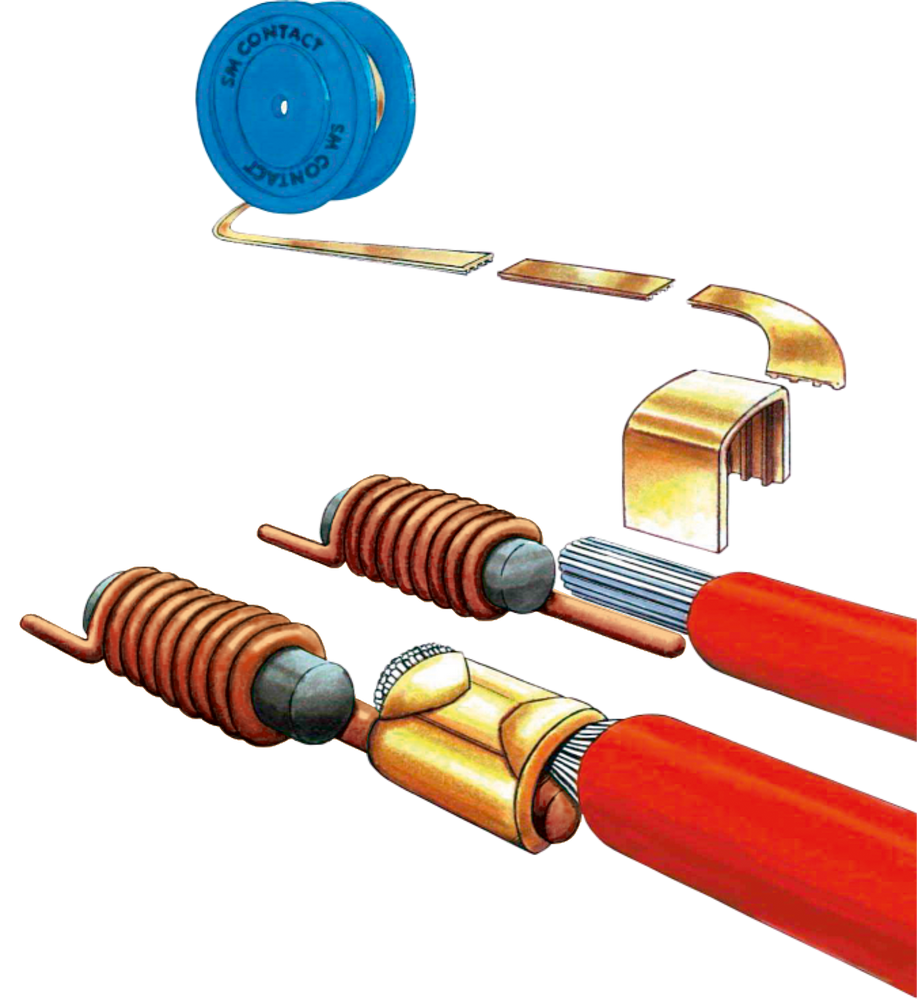

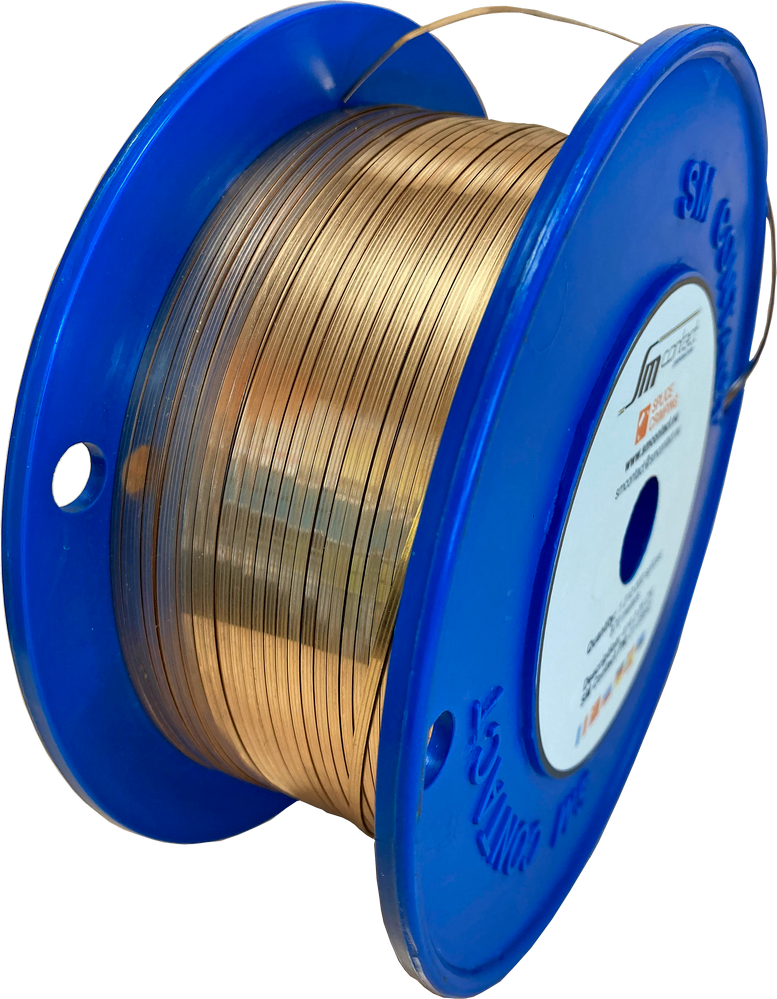

Terminals and splices provide the same solderless crimp technology for magnet wires, while splice is more cost-effective per connection. SM Contact offers P-type splice band (where “P” means piercing) with SM Crimp machines which enable stable high productivity with using the same bobbin for different wire sizes and no wasted material.

Both terminals and splices terminate magnet wire through crimp compression in coils, motors, compressors, transformers, power supplies and other windings. Sharp serrations penetrate varnish coating of a magnet wire and produce robust gastight electrical connection with no pre-stripping. It’s applied instead of soldering and spot welding.

Processing method

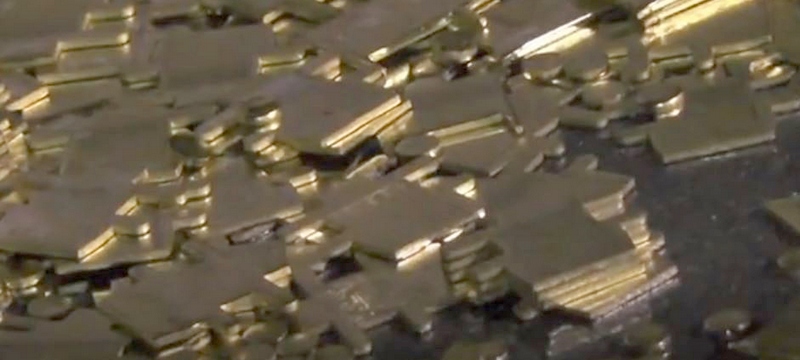

Crimp terminals are stamped from the carrier band with a die tool. Except the completed terminals, we get scraps and cuts. Even though this waste material is reused, it still adds to the cost. Also change of the terminal configuration and pitch require new mold production.

| Crimp terminals manufacturing | ||

|

|

|

| Carrier band | Completed terminals | Loss of material (scraps) |

In comparison to stamping, effectiveness of using the material in splicing is higher:

— no stamping out of material, no loss of material,

— tooling costs are cheaper.

So this solution is more advantageous in terms of price per contact.

Comparison of crimp terminals and splices for magnet wire termination

SM Crimp machines provide a precisely controlled process of splice crimping in magnet wire connections. Each project is started with profound connection and tooling qualification. The optimal parameters are kept in the machine memory. Readjustment with each new connection is done automatically, reducing the risk of production errors.

If you’re terminating magnet wire, discover more about SM Contact technology with P-type splice band: +34 919490803, smcontact@smcontact.eu